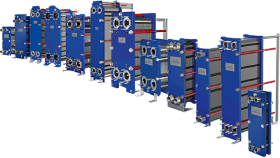

All the heat exchangers in this

brochure have connections in the frame plate. They are referred to as S1, S2, S3 and S4. The

gasketed heat exchanger can be placed directly on the floor. When possible, it is always safer to secure the unit with foundation bolts. The

plate heat exchanger is noted for occupying less space than traditional heat exchangers. When planning the space recommended, it is necessary to leave space on one side of the heat exchanger only. The pipe connections can be either screwed or flanged, depending on the type of heat exchanger selected.

The

brazed plate heat exchanger will normally be built into the pipework, or

mounted into a small console. The inlet of one medium is next to the outlet of the other. If S1 is the inlet for medium 1, then S4 is the outlet for medium 2. Every heat exchanger delivered is accompanied by instructions as to which I let and outlet to use. Depending Upon the type of connection selected, prepare the pipework with screwed thread ends, fit flanges or prepare for welding.

Some of the

accessories available for the plate heat exchangers are insulation, drip trays, and protection sheets.