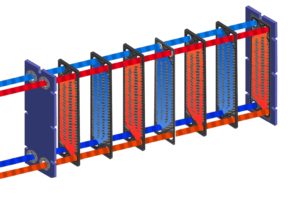

In the realm of dairy production, heat exchangers play a crucial role in ensuring the safety and quality of dairy products. Let’s delve into the technical intricacies of how these machines operate to guarantee the utmost standards in dairy pasteurisation.

- Precise Temperature Control: Heat exchangers excel at maintaining precise temperature control during the pasteurisation process. This precision is critical for eliminating harmful microorganisms while preserving the nutritional quality of the dairy products. With a temperature control accuracy within fractions of a degree, heat exchangers ensure that the pasteurisation conditions are optimal for product safety and quality.

- Efficient Heat Transfer: These machines facilitate the quick and uniform heating of raw dairy to the required pasteurisation temperature. It ensures that the entire product is treated consistently. With advanced heat transfer technology, heat exchangers swiftly and evenly distribute heat throughout the dairy, minimising processing time and maximising efficiency.

- Rapid Cooling Mechanism: Following pasteurisation, the heat exchangers swiftly initiate the cooling phase. This rapid cooling is essential to prevent any post-pasteurization contamination and to maintain the desired texture and flavour of the dairy products. By expediting the cooling process, heat exchangers contribute to the swift transition from high temperatures to safe storage conditions.

- Scalability for Large Batches: Heat exchangers are designed to handle varying production scales, from small batches to large quantities. This scalability ensures that the pasteurisation process remains consistent and efficient regardless of the production volume. Whether processing a few litres or several thousand litres, heat exchangers offer the adaptability needed for diverse dairy production demands.

- Standardisation of Product Quality: Consistency is paramount in the dairy industry. Heat exchangers contribute to this by standardising the pasteurisation process, guaranteeing that each batch of dairy products meets the same quality and safety standards. Through precise control over pasteurisation parameters, heat exchangers play a key role in achieving uniform and standardised product quality.

- Energy-Efficient Operations: In addition to their precision, heat exchangers are recognized for their energy efficiency. These machines are engineered to optimise energy consumption, aligning with sustainable practices in industrial dairy processing. By minimising energy wastage and maximising heat recovery, heat exchangers contribute to environmentally conscious and cost-effective dairy production.

In summary, heat exchangers play a vital role in the dairy pasteurisation process by ensuring precise temperature control, efficient heat transfer, rapid cooling, scalability for varying production volumes, standardisation of product quality, and energy-efficient operations. Their technical prowess contributes to the production of safe and high-quality dairy products on a consistent basis.

Read Also

Efficiency of Heat Exchanger: Factors that affect performance