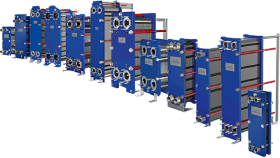

A strategic selection of heat exchangers plays a crucial role in industrial processes. Plate-type heat exchangers often play the role of unsung heroes and prove instrumental in specific scenarios. They are also known to offer unparalleled efficiency and adaptability.

Let’s explore such circumstances where using plate-type heat exchangers becomes extremely important.

1. Optimal Space Utilisation:

Efficiency in Constricted Spaces: Plate heat exchangers excel where spatial constraints are critical. Their compact design ensures high-performance heat exchange without compromising on square footage—an ideal solution for facilities with premium space.

2. Managing High-Viscosity Fluids:

Proficiency in Viscous Environments: When dealing with thick or viscous fluids, plate-type heat exchangers emerge. Their design enables them to navigate through high-viscosity substances seamlessly, maintaining efficiency across various industrial processes.

3. Versatility in Temperature Management:

Adapting to Diverse Thermal Requirements: Plate exchangers demonstrate remarkable adaptability to handle both low and high-temperature fluids. This versatility makes them a preferred choice for industries with fluctuating thermal demands.

4. Emphasising Cleanability:

Effortless Maintenance: Plate-type heat exchangers prioritise easy cleaning. Their design allows for swift disassembly and cleaning processes, minimising downtime and ensuring streamlined and efficient operations.

5. Cost-Effective Cooling Solutions:

Energy-Efficient Cooling: Plate heat exchangers stand out for their energy-efficient operation, translating to substantial cost savings. These heat exchangers are a reasonable investment if you want to cool fluids economically.

6. Accommodating Liquid-Gas Exchange:

Versatility Across Applications: Plate-type heat exchangers exhibit versatility by efficiently managing liquid-liquid exchange and liquid-gas exchange. This adaptability positions them as suitable solutions for various industrial applications.

7. Swift Response to Temperature Changes:

Responsive Temperature Adjustments: Plate exchangers take the lead in processes demanding rapid temperature changes. Their design facilitates quick adjustments, ensuring operational agility to meet dynamic requirements.

8. Seamless Integration in System Upgrades:

Smooth Transition: When contemplating upgrading your existing heat exchange system, plate-type exchangers offer a seamless transition. Their adaptability and compatibility make them valuable additions for modernising industrial processes.

Selecting a suitable heat exchanger is similar to selecting the right tool for the job. Plate-type heat exchangers come into prominence under certain conditions. They provide unmatched efficiency, adaptability, and cost-effectiveness. It’s time to elevate plate-type heat exchangers to a central role when the industrial processes demand this unique combination.