Heat transfer is a key process in many industries, from power plants to chemical factories. One of the most widely used devices for heat exchange is the shell and tube heat exchanger. In this blog, we will explore how heat is transferred in these exchangers and how their design influences performance. Also, we’ll look at why they’re preferred over other types, like the plate heat exchanger. Understanding these concepts is helpful for anyone interested in mechanical engineering or industrial processes.

What is a Shell and Tube Heat Exchanger?

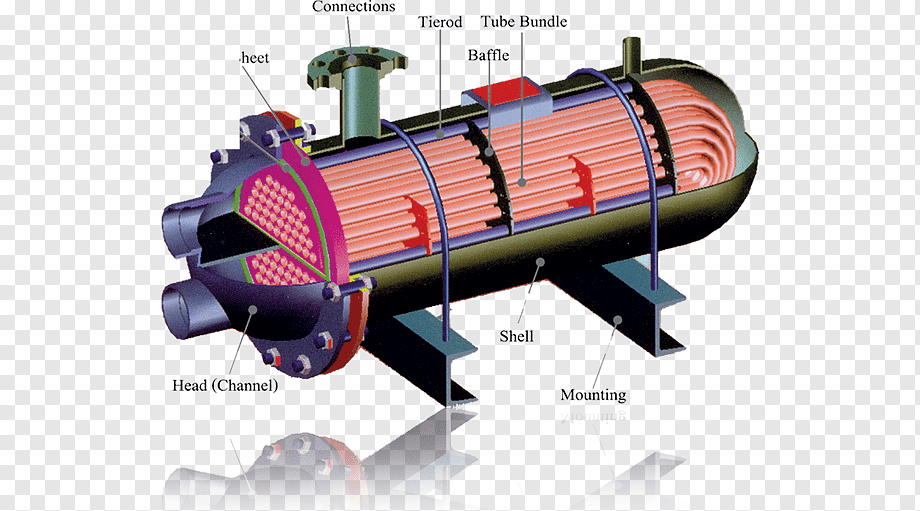

A shell and tube heat exchanger is designed to facilitate the transfer of heat between two different fluids. It consists of a large cylindrical shell (the outer body) and several tubes inside it. One fluid moves through the tubes, while the other flows around the exterior of the tubes inside the shell. The two fluids do not mix, but heat is exchanged through the tube walls.

These types of heat exchangers have flexibility and the ability to handle high pressure and temperature. These heat exchangers are known for their high efficiency and are utilized across various applications.

How Does Heat Transfer Occur in Shell and Tube Exchangers?

Heat transfer in shell and tube heat exchangers happens through three main mechanisms: conduction, convection, and occasionally radiation. The method involves two fluids: one that moves through the tubes and another that flows around them in the shell. Here’s a closer look at the process:

Conduction

Heat moves through the walls of the tubes. The hotter fluid, whether inside the tubes or in the shell, transfers heat to the cooler fluid through conduction as heat passes through the metal of the tube walls.

Convection

As the fluids flow, heat is transferred to and from the tube surfaces. For instance, when a hot fluid flows through the tubes, heat is transferred to the tube walls, which then pass this heat to the cooler fluid in the shell. The rate of this heat transfer depends on the fluid flow rates and their thermal properties.

Flow arrangements

The direction in which the fluids move also influences heat transfer efficiency:

Counterflow: Fluids move in opposite directions, which is the most efficient as it maintains a greater temperature difference between the two fluids.

Parallel flow: Fluids move in the same direction, but this results in less efficient heat transfer.

Crossflow: Fluids flow perpendicular to each other, a design often used in real applications.

In essence, heat transfer occurs from the hotter to the cooler fluid across the tube walls, primarily by conduction, while the movement of fluids enhances this transfer through convection.

Why Design Impacts Performance

The design of a shell and tube heat exchanger plays a big role in how effectively it transfers heat. Here are the main design factors that influence performance:

1. Tube Design and Arrangement

The number, length, and diameter of the tubes all impact the heat transfer rate. More tubes or longer tubes provide a larger surface area for heat exchange. The arrangement of the tubes (e.g., in a straight line or U-shaped) also affects how the fluids flow and how much heat is transferred.

2. Flow Pattern

Heat exchangers can have different flow patterns, such as parallel flow (where both fluids move in the same direction) or counterflow (where fluids move in opposite directions). Counterflow designs are generally more efficient because they sustain a greater temperature difference between the fluids throughout the heat transfer.

3. Shell Design

The size and shape of the shell also matter. A larger shell allows for a higher volume of fluid flow, which can improve the heat transfer rate. Additionally, baffles (small plates inside the shell) are used to direct the fluid flow, increasing turbulence and improving heat transfer.

4. Material of Construction

The materials used in the tubes and shell determine how quickly heat is transferred. Metals like copper or stainless steel are good conductors and are often used to improve performance. Additionally, the selection of materials can impact both the longevity and cost of the heat exchanger.

Shell and Tube vs. Plate Heat Exchangers

Although plate heat exchangers are another common option, shell and tube heat exchangers have several advantages. Shell and tube designs can handle higher pressures and temperatures, making them more suitable for industrial use. They also offer more flexibility in terms of size and are easier to clean and maintain. While plate heat exchangers are more compact and efficient for small systems, shell and tube exchangers are preferred for large-scale operations.

Conclusion

Shell and tube heat exchangers are essential components in many industries, and their design directly affects their performance. Factors like tube arrangement, flow patterns, and the material used all play a role in how efficiently heat is transferred. By understanding these basics, you can get the correct device for your purpose from a reputed shell and tube heat exchanger manufacturer like Pragya Associates. We prioritize thoughtful design and engineering to ensure that our products deliver optimal performance in even the most demanding environments.