Pragya Associates is a prominent shell and tube heat exchanger manufacturer and supplier offering heat exchangers that efficiently exchange heat between two fluids in engines, transmissions, and hydraulic power systems in different Industries. We provide an extensive variety of products to fulfil our customers’ requirements. Our products are used in a variety of industries, including oil and gas, petrochemicals, power generation, and food processing. Designed for long-lasting performance, our heat exchangers save energy and reduce costs. We focus on quality to meet our customers’ needs. We are dedicated to delivering products and services of the utmost quality to our customers.

About Shell And Tube Heat Exchanger

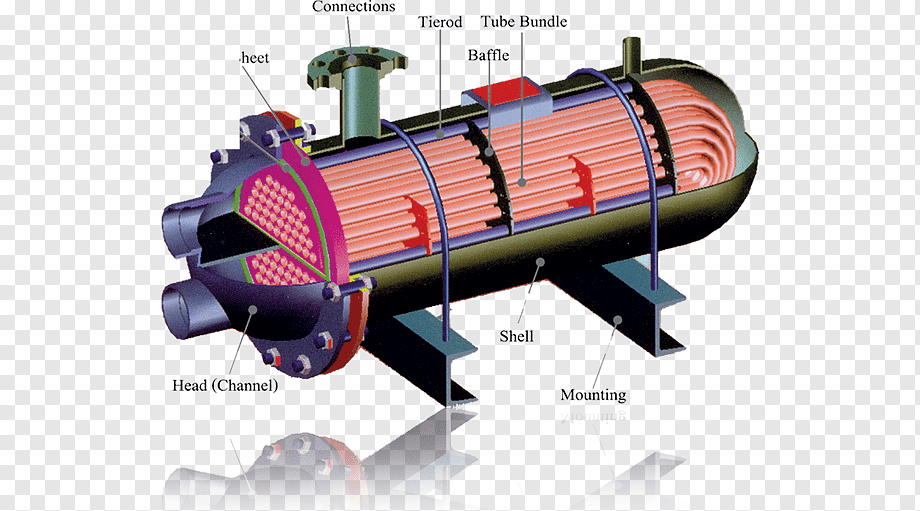

Shell and tube heat exchanger is a type of heat exchanger that efficiently exchanges heat between two fluids in engines, transmissions, and hydraulic power systems in different Industries. Shell and tube heat exchangers are used in many comfort and industry applications for heating and cooling fluids. They consist of a shell with traditional plain tubes or enhanced surface tubes for high thermal performance. The fluids can be liquids or gases, one of which flows inside the tubes while the other flows outside the tubes within the shell. There are single-phase or two-phase heat exchangers, and the latter is used to either boil or condense fluids. Shell & Tube Heat Exchangers are most commonly used in almost all industries like- Refineries, Chemical plants, Fertilizer plants, Genset units, Oil & Gas, and Shipping. The typical use of the Alfa Laval Heat Exchanger is to cool or heat the fluids or gases. As the leading and reliable heat exchanger manufacturer, we have been providing high-quality products to our customers for years.

Shell and tube heat exchangers are widely used throughout the engineering world and are among the two most common types of heat exchangers; The other common type is the plate heat exchanger.

Shell and tube heat exchangers have a simple structure, robust properties and relatively low acquisition and maintenance costs. They also have a very high rate of heat transfer, although they take up more space. than a plate heat exchanger heat exchanger with a similar heat exchange capacity.