In the vast world of petrochemical refining, certain equipment plays a vital role in ensuring smooth operations and product quality. One such piece of equipment is the shell and tube heat exchanger. Let’s delve into how these exchangers work and their importance in petrochemical refining processes.

Understanding Shell and Tube Heat Exchangers:

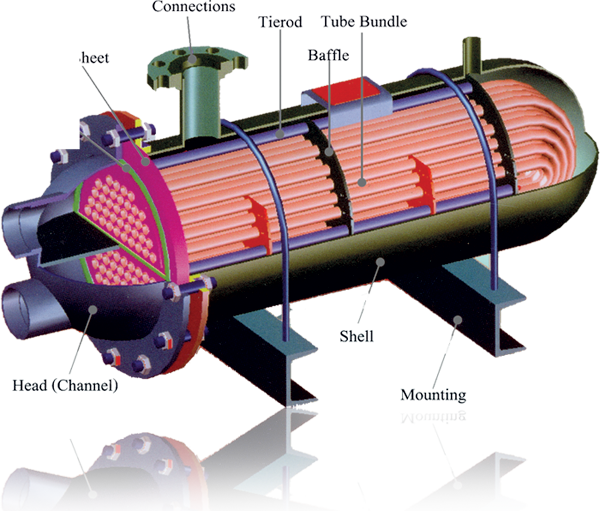

Shell and tube heat exchangers are essential components in petrochemical refining plants. They consist of a bundle of tubes enclosed within a shell. One fluid flows through the tubes while another flows around them, allowing for the exchange of heat between the two fluids.

How They Work:

The process begins with one fluid, often a hot oil or gas, flowing through the tubes. As it travels through the tubes, it transfers heat to the surrounding fluid flowing around the tubes, typically a cooler substance such as water or air. This transfer of heat helps to either heat or cool the surrounding fluid, depending on the desired outcome of the refining process.

Importance in Petrochemical Refining:

Shell and tube heat exchangers are integral to various stages of petrochemical refining. They are used to heat crude oil to separate it into its various components, such as gasoline, diesel, and jet fuel. Additionally, they play a crucial role in cooling down hot gases and liquids generated during the refining process.

Efficiency and Reliability:

One of the key advantages of shell and tube heat exchangers is their efficiency and reliability. These exchangers are designed to handle high temperatures and pressures commonly found in petrochemical refining operations. Their robust construction and simple design make them well-suited for the demanding conditions of the industry.

Maintenance and Safety:

Proper maintenance of shell and tube heat exchangers is essential to ensure their continued performance and safety. Regular inspections and cleaning help prevent fouling and corrosion, which can reduce efficiency and compromise safety. Additionally, adherence to strict safety protocols is crucial to prevent accidents and ensure the well-being of plant personnel.

In conclusion, shell and tube heat exchangers are indispensable components of petrochemical refining processes. Their ability to efficiently transfer heat between fluids plays a critical role in heating, cooling, and separating various substances during the refining process. With their efficiency, reliability, and importance in ensuring product quality and safety, shell and tube heat exchangers are truly the unsung heroes of the petrochemical industry.