Heat transfer skids are essential equipment used in many industries. They play an important role in ensuring that industrial processes run smoothly and efficiently. They help manage and transfer heat between different fluids in a controlled manner. Heat Transfer Skids are particularly valuable in industries such as chemical processing, oil and gas, and food production. Let’s dive into what these skids are, how they work, and why they are important.

What is a Heat Transfer Skid?

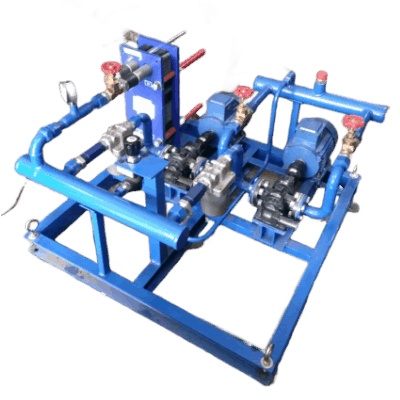

A heat transfer skid is a pre-assembled unit designed to handle the transfer of heat between fluids. It’s like a self-contained system that has everything that is required for effective heat exchange. Typically, it has components like heat exchangers, pumps, valves, and control systems—all mounted on a single framework or “skid.” This modular design makes it easy to install and operate in various industrial environments.

How Does a Heat Transfer Skid Work?

The basic idea behind a heat transfer skid is to move heat from one fluid to another. For this, a heat exchanger is integrated into the skid to enable heat transfer. Inside the heat exchanger, hot fluid flows through one set of channels, while the cooler fluid flows through another. Heat is transferred from the hot fluid to the cooler one, raising the temperature of the cooler fluid.

For example, a heat exchanger within a heat transfer skid can transfer heat from hot oil to water. The hot oil flows on one side of the exchanger while the water flows on the other. The heat moves from the hot oil to the water. It is strictly monitored to keep the process efficient and effective.

Key Components of a Heat Transfer Skid

An effective heat transfer skid consists of several key components. The most important component is the heat exchanger. Without causing the fluids to mix, this device enables heat to transfer between them. Pumps are necessary for moving the fluids throughout the system. Valves control the flow and pressure of the fluids, ensuring everything works smoothly. Finally, the control system monitors and adjusts the operation to maintain optimal performance.

Why Are Heat Transfer Skids Important?

Heat transfer skids are important for several reasons. First, they help improve energy efficiency. By transferring heat effectively, these systems reduce the need for additional energy to heat or cool fluids. This can result in big savings. Second, they enhance process safety. By managing heat transfer precisely, skids help prevent overheating and other issues that could lead to accidents or equipment damage. Finally, their modular design allows for easy installation and maintenance, saving time and effort.

Applications in Different Industries

Heat transfer skids are used in various industries. In chemical processing, they manage the heat required for reactions. In oil and gas, they help control temperatures during extraction and refining. In the food and beverage industry, they ensure that products are heated or cooled to the right temperatures. Each of these applications benefits from the efficiency and reliability of heat transfer skids. Thus, it makes them versatile and valuable tools in many fields.

Conclusion

In numerous industrial procedures, heat transfer skids are an essential component. They efficiently transfer heat between fluids, helping to maintain optimal temperatures and improve overall efficiency. These systems ensure safe and effective operation with their modular design and key parts like pumps and heat exchangers. Understanding how they work will help to know the value of these machines in various industries. This helps you see why they are so important in today’s industrial processes.

Trust Pragya Associates for high-quality heat transfer skids that deliver reliable performance. We offer dependable heat transfer skids designed for your specific needs.