In today’s industrial world, energy costs can be very high. That is why industries always look for ways to reduce these costs. One effective method to achieve this is optimizing the energy use of cooling skids. Cooling skids are essential in many industries. They help regulate temperatures and keep equipment running smoothly. But when they use too much energy, they become costly to operate. In this blog post, we’ll explore how optimizing energy use in cooling skids can save money.

What Are Cooling Skids?

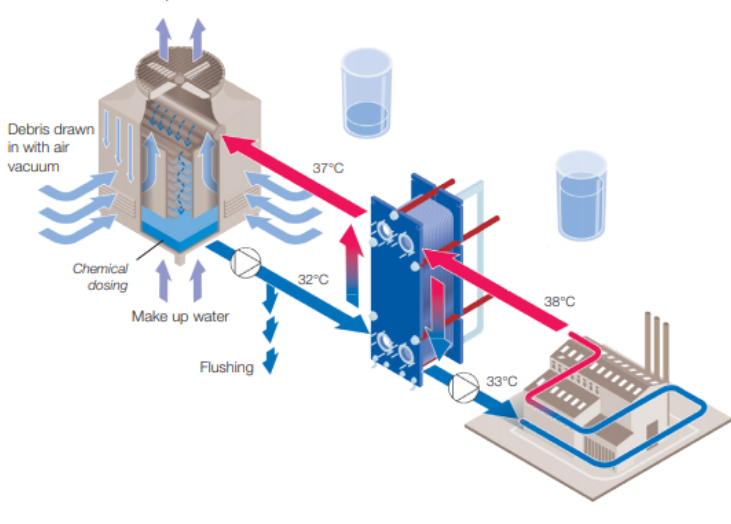

First, let’s understand what cooling skids are. A cooling skid is a compact system that includes various components. These components usually consist of heat exchangers, pumps, filters, and controls. They are used to remove heat and keep things cool, allowing machinery to function correctly. They reduce overheating and make sure everything runs smoothly.

Why Energy Optimization Is Important

Energy optimization means using less energy to perform the same tasks. This is important because it reduces operational costs. Furthermore, lower energy consumption also means a smaller carbon footprint, which is good for the environment. So, optimizing energy use in cooling skids is a win-win situation.

Steps to Optimize Energy Use in Cooling Skids

Regular Maintenance

Regular maintenance is crucial for energy optimization. When components are clean and in good condition, they work more efficiently. On the other hand, dirty filters or clogged pipes make the system work harder, using more energy. This can be avoided by inspecting and cleaning the equipment on a regular basis.

Use Efficient Components

Selecting energy-efficient components can significantly reduce operating costs. For example, choosing energy-efficient pumps and heat exchangers is a smart choice. Although modern, energy-efficient models may require a higher initial cost, the long-term savings on energy costs usually surpass the original cost. By making this change, you’re improving both your financial situation and the sustainability of the environment.

Proper Sizing

The size of your cooling skid is an important factor that you should carefully evaluate to improve overall system performance and energy efficiency. Oversized skids waste energy, resulting in increased costs, while undersized systems can’t meet cooling needs, risking equipment damage and reduced output. To ensure that you get the best cooling skid for your specific demands, consult experts. They will examine your cooling requirements and suggest the most appropriate system.

Variable Speed Drives (VSDs)

Variable Speed Drives (VSDs) control the speed of pumps and fans. Depending on the specific needs of the system at any given time, these mechanisms control the speed of these various components. This dynamic adjustment is a key component of energy efficiency. VSDs help to reduce energy expenditures while maintaining system performance by minimizing overwork and needless power use.

Insulation

Proper insulation of pipes and other components can prevent energy loss. This process involves wrapping these elements with a specialized material designed to retain heat or cold. Insulation helps in maintaining the system’s optimum temperature by limiting heat loss to the outside environment. This, in turn, reduces the workload on the equipment, as it doesn’t have to expend as much energy to compensate for heat loss. As a result, it maintains optimal temperatures, resulting in lower energy consumption and cost savings.

Energy Monitoring Systems

Keeping tabs on energy use is super important. That’s where energy monitoring systems come in handy. They show you exactly how much energy your cooling skid is using right now. This data is quite useful for optimizing processes and helps you spot any energy wasters and fix them before they cause big problems. By tracking and analyzing energy use, you can make smart decisions that can help in cutting costs and reducing environmental impact. Also, it improves the efficiency of your cooling skid.

Heat Recovery

Some cooling skids can be equipped with heat recovery systems. These machines collect waste heat and use it to heat air or water for different purposes. By doing this, the total amount of energy needed for heating other areas is decreased. As a result, a considerable amount of energy is saved, and the machine’s efficiency is increased. Industries that use waste heat can save money on energy and lessen their environmental effect.

Regular Training for Operators

Operators should be trained regularly on energy-efficient practices. They should know how to operate the cooling skid in the most efficient way. Regular training sessions should cover best practices and troubleshooting techniques for operating the cooling skid. Also, operators should be taught to understand how operational choices affect energy use. Proper training ensures that everyone is aware of best practices and follows them. This allows companies to considerably decrease their energy use.

Benefits of Energy Optimization

Optimizing energy use in cooling skids has several benefits. The most obvious is cost savings. Lower energy bills mean more money can be invested in other areas of the business. Additionally, it prolongs the equipment’s lifespan. When the system is not overworked, it lasts longer, reducing the need for replacements.

Additionally, using less energy is better for the environment. It reduces the release of greenhouse gases while also helping to combat climate change. Industries that focus on energy efficiency can also enhance their reputation. Customers and clients appreciate businesses that are environmentally responsible.

Conclusion

Energy optimization in cooling skids is a smart move for any company. It reduces operational costs, extends equipment life, and benefits the environment. By following these simple steps, you can ensure your cooling skids run efficiently. Regular maintenance, using efficient components, and proper training are key. Purchasing an energy-efficient cooling skid from Pragya Associates, a reputable supplier, is a wise decision. It will save you money while also improving your operational efficiency.