When it comes to industrial processes in India, choosing the right equipment is crucial. One such important piece of equipment is the heat transfer skid. Heat transfer skids play a vital role in various industries, helping manage temperatures in processes that require heating or cooling. But with so many options available, how do you choose the correct one for your specific requirements? This blog will guide you through the process of selecting the perfect heat transfer skid for your industrial application.

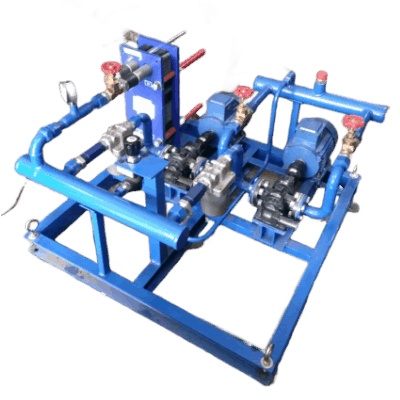

What is a Heat Transfer Skid?

A heat transfer skid is a compact, pre-assembled system used to transfer heat from one fluid to another. It consists of components like heat exchangers, pumps, valves, and control systems, all mounted on a single skid or frame. These skids are designed to efficiently manage heating or cooling in industrial processes. They ensure that your industrial operations run smoothly and effectively.

Why is the Right Heat Transfer Skid Important?

Choosing the right heat transfer skid is critical for the efficiency and safety of your industrial processes. An incorrectly chosen skid can lead to poor performance, higher energy costs, and potential safety dangers. Moreover, the right skid ensures that your processes maintain the required temperature, which is essential for product quality and consistency.

Factors to Consider When Choosing a Heat Transfer Skid

1. Understanding Your Application Needs

The first step in selecting the right heat transfer skid is understanding your specific application. Different industries have different requirements. For example, the chemical industry may need a skid for precise temperature control. On the other hand, the food and beverage industry might prioritize hygiene and ease of cleaning. Understanding your application needs will help you narrow down your choices.

2. Capacity and Flow Rate

The capacity and flow rate of the skid are crucial factors. Capacity refers to the amount of heat that a skid can transfer, and the flow rate refers to the volume of fluid that passes through the system. Both of these should match your process requirements. A skid with insufficient capacity or flow rate can lead to inefficiencies and potential process disruptions.

3. Temperature Range

Consider the temperature range your process requires. Some processes need very high temperatures, while others might need cooling. While choosing a skid for your operations, make sure that it can handle the maximum and minimum temperatures your process demands. As a result, this will prevent any damage to the system and maintain the quality of your output.

4. Material Compatibility

The materials used in the construction of the heat transfer skid must be compatible with the fluids in your process. For example, if you’re dealing with corrosive chemicals, the skid should be made of corrosion-resistant materials. This ensures longevity and prevents contamination of your products.

5. Energy Efficiency

When choosing a skid, considering energy efficiency is important, especially in India, where energy costs can be high. An energy-efficient skid will reduce operational costs and minimize your environmental impact. That is why always look for skids with high-efficiency heat exchangers and pumps. These elements have a major impact on the total amount of energy used.

6. Ease of Maintenance

Regular maintenance is essential for the longevity and performance of a heat transfer skid. You can save time and money in the long run by selecting a skid that requires less maintenance. Before making any selection, consider component accessibility, spare parts availability, and the support provided by the manufacturer.

The Role of a Trusted Manufacturer

Choosing the right heat transfer skid also involves selecting the right manufacturer. A trusted manufacturer with experience in your industry can provide valuable insights and support. They can help you select a skid that perfectly fits your needs, ensuring that it is designed and built to the highest standards. They can also provide maintenance and troubleshooting services as part of their after-sale support service.

Conclusion

Selecting the right heat transfer skid for your Indian industrial application needs careful consideration of various factors. Understanding your process needs, choosing the right capacity and flow rate, considering material compatibility, and prioritizing energy efficiency are all essential steps. Partnering with a reliable manufacturer can further enhance your experience, ensuring you get a skid that meets your needs and exceeds your expectations.

By choosing the right heat transfer skid, you ensure the efficiency, safety, and profitability of your industrial processes. This decision is not just about buying equipment; it’s about investing in the future success of your operations. So, make a wise decision that will benefit you for many years to come.