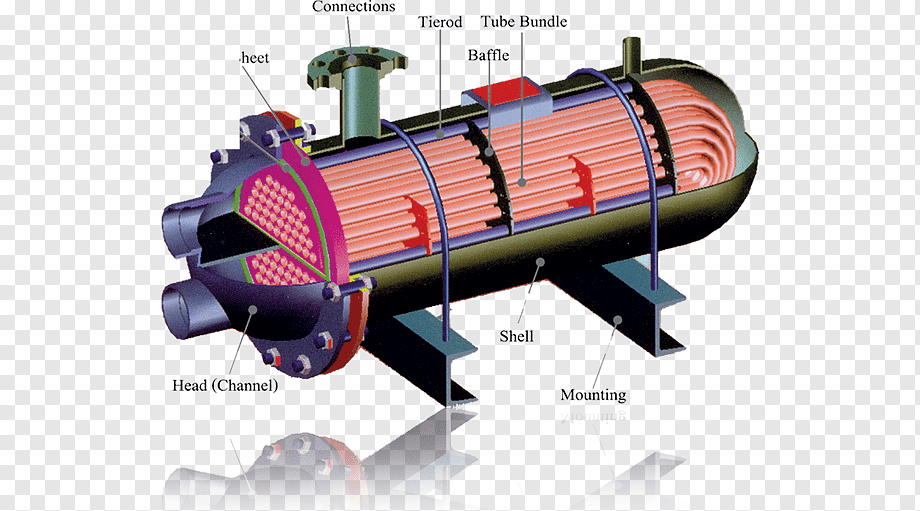

Shell and tube heat exchangers are important components in various industrial processes, facilitating efficient heat transfer between fluids. From power plants keeping our lights on to refineries turning crude oil into fuel, these machines play a vital role. But like any machine, proper care is essential to ensure they function optimally and last for years. By following these simple steps, you can extend the life of your shell and tube heat exchanger, saving money and avoiding costly downtime.

- Schedule Regular Cleaning: The Importance of Fighting Fouling

Over time, your heat exchanger can accumulate dirt, debris, and mineral deposits like a clogged drain. This buildup, called fouling, acts as a thermal insulator, lowering heat transmission efficiency. To mitigate this issue:

- Based on operational parameters and fluid traits, create a cleaning schedule.

- Consult manufacturer guidelines for recommended cleaning intervals

- Utilize appropriate cleaning methods such as mechanical cleaning, chemical treatments, or hydro-jetting

- Adjust cleaning frequency for challenging environments (e.g., marine applications with high mineral content)

Consistent cleaning practices maintain thermal efficiency and reduce energy consumption.

- Don’t Neglect Maintenance: Catching Problems Early Saves Big

Proactive maintenance is important for recognizing possible problems before they become serious. Regular maintenance is key to keeping the machine running smoothly and avoiding breakdowns. Below are the essential focus areas for keeping a heat exchanger in top condition

- Tube integrity: Check for erosion, corrosion, and leaks.

- Gasket condition: Assess for wear or degradation to prevent fluid leakage

- Mechanical components: Evaluate and service moving parts as needed

Regular inspections minimize the risk of unexpected failures and costly downtime.

- Optimize Fluid Flow Rates

Shell and Tube Heat Exchangers rely on a specific flow rate of fluids. If the flow rate is too slow, it won’t efficiently carry the heat away. Conversely, a flow rate that’s too fast, can damage the tubes and internal components due to excessive pressure. Maintaining appropriate fluid velocities is essential for efficient heat transfer and equipment longevity, otherwise:

- Insufficient flow can decrease heat transfer and cause fouling

- Excessive flow may cause erosion and mechanical stress

Implement flow monitoring systems and adjust pump settings to maintain optimal flow rates. This practice enhances heat transfer efficiency while protecting the exchanger’s internal components.

- Anticipate and Plan for Operational Changes

Operational modifications can significantly impact heat exchanger performance. Perhaps you’re switching to a different fluid with a higher viscosity (thickness), or maybe your production rate is increasing, requiring more heat transfer. In these scenarios, your existing heat exchanger might not be able to handle the new demands. When considering changes:

- Assess if the fluid is compatible with the construction materials currently in use

- Analyze the effect on the requirement for heat transfer.

- Consider potential adjustments to flow rates or pressure differentials

Proactive planning ensures your heat exchanger can adapt to evolving process needs without compromising efficiency or integrity.

- Keep Records

Accurate record-keeping is fundamental for effective asset management:

- Document all maintenance activities, including cleaning procedures and repairs

- Track metrics over time to find patterns in performance

- Record any anomalies or unexpected events

This data facilitates informed decision-making regarding maintenance schedules, component replacements, and potential upgrades.

- Engage Specialized Expertise When Necessary

While routine maintenance can often be handled in-house, certain situations warrant professional intervention:

- Complex chemical cleaning processes

- Major repairs requiring specialized welding or fabrication

- Troubleshooting persistent performance issues

Using specialist expertise ensures that complex maintenance jobs are completed safely and efficiently.

The Impact of Effective Maintenance

Implementing a robust maintenance strategy for shell and tube heat exchangers yields several benefits:

- Enhanced operational efficiency, resulting in reduced energy costs

- Minimized unplanned downtime, improving overall process reliability

- Extended equipment lifespan, deferring capital expenditure on replacements

By adhering to these maintenance principles, organizations can maximize the value of their heat exchange assets, ensuring consistent performance in demanding industrial environments.

Effective maintenance of shell and tube heat exchangers is a critical factor in sustaining efficient industrial processes. By implementing regular cleaning protocols, conducting systematic inspections, optimizing fluid dynamics, anticipating operational changes, maintaining comprehensive records, and leveraging specialized expertise when needed, organizations can significantly enhance the performance and longevity of these essential components. This proactive strategy not only ensures operational reliability but also helps to save long-term costs.